Corrosion & Corrosion Protection

CORROSION - A CHALLENGE

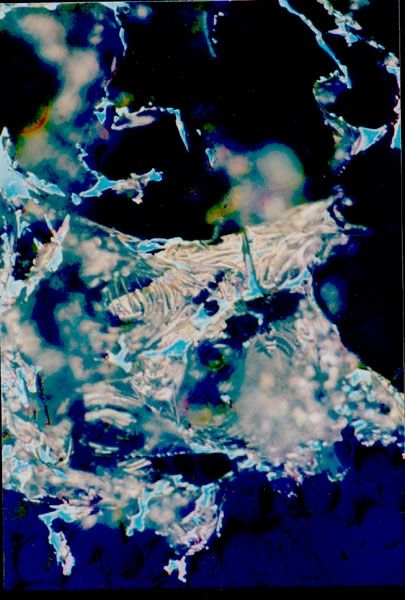

Unfortunately, most of the materials used to realise our civilised environment are not chemically stable. Energy is consumed to convert ores into metals. Consequently, metals degrade at a certain velocity, increasing the state of entropy. Thus, corrosion is an unavoidable effect governed by physico-chemical rules.

Corrosion is one of the most deleterious chemical phenomena affecting our economies. Recent studies showed that in the USA, the cost of corrosion loss piled up to $ 70 000 000 000 in 1980 , and to $ 180 000 000 000 in 1986. In other terms, 4.2% of the US gross national product were spent for substitution of corrosion losses. This percent-age is similar in other countries, too. Moreover, corrosion damages often cause human disease or casualties.

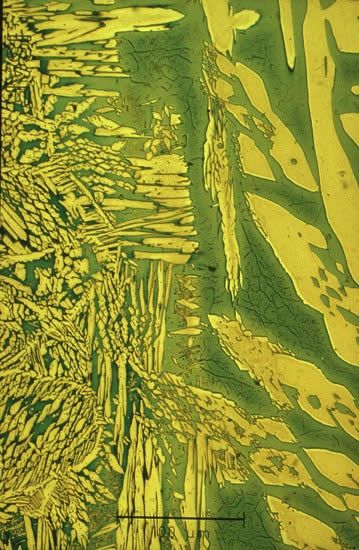

These studies concluded, that 15% or more of these costs could be saved only by applying the current available knowledge of corrosion mechanisms and the technologies of corrosion control. Another aspect concerning our future is the conservation of rare materials. Nickel, for instance, is one of the strategic materials widely used in corrosion resistant alloys, and it is rather expensive. Intelligent use of this metal means to save money - ours and our children. A lot of studies and laboratory testing done at DN corrosion laboratory dealt with the substitution of nickel-rich alloys by nickel-saving duplex stainless steels, which often show a performance comparable to austenitic alloys or better.

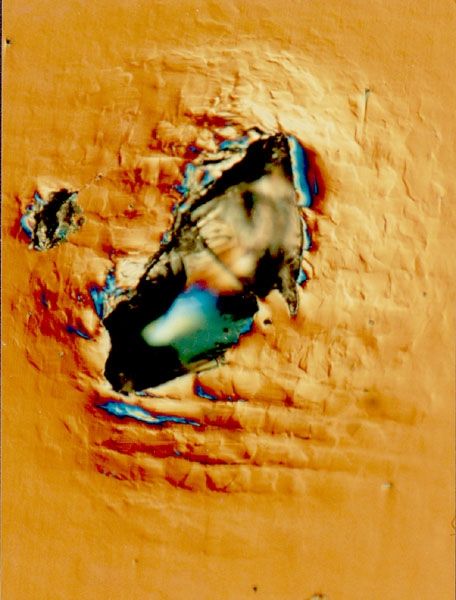

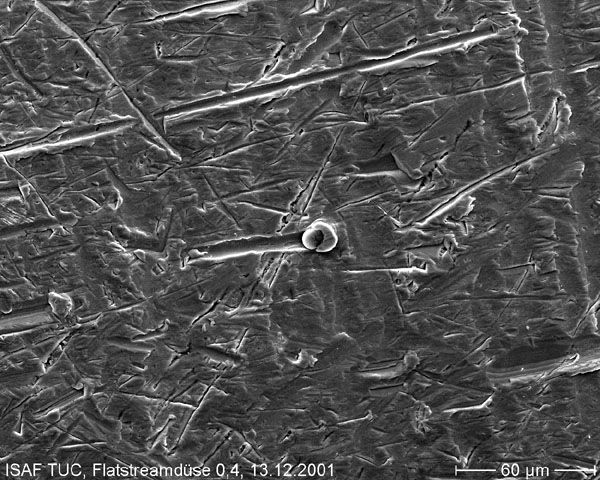

Novel construction materials, as well as novel coatings or surfacing welding, e.g. have to witness their performance. DN is active in this field. Both laboratory capacities and inventive testing techniques are available. DN elaborated programmes for testing carbon - fibre reinforced plastics, novel weld plating and powder - metallurgical HIP - alloys and conducted the tests.

CORROSION ENGINEERING

Corrosion, or corrosion damages, originate from the interaction of rather different influences. The corrosion engineer must be able to detect those influences and to assess their interactions. His view has to include either material science, metallurgy, chemistry, physics, mechanics and production techniques. DN corrosion research and consulting is done by personnel having a wide working knowledge of processes and practice in a lot of industries. It is DN's philosophy to assemble a variety of engineers and scientists from the most possible areas of interest: Corrosion engineers, material scientists, welding engineers, foundry engineers, civil engineers and oil and gas engineers.